Instrument

The NASA Airborne Visible/Infrared Imaging Spectrometer (AVIRIS) has been in operation since 1989 acquiring contiguous spectral measurements between 380 and 2510 nm for use by a range of terrestrial ecology science investigations related to: (1) pattern and spatial distribution of ecosystems and their components, (2) ecosystem function, physiology and seasonal activity, (3) biogeochemical cycles, (3) changes in disturbance activity, and (4) ecosystems and human health. While AVIRIS continue to make unique and significant science contributions, such as its deployment to the Gulf of Louisiana in May 2010 for the assessment of the amount of oil spilled by the offshore well, the need for a new sensor to share AVIRIS’ workload and to eventually replace AVIRIS is inevitable. Indeed, since the late summer of 2009 a new NASA Earth Science airborne sensor called the Next Generation Airborne Visible/Infrared Imaging Spectrometer (AVIRIS-NG) is being developed by JPL through the funding support from the American Recovery and Reinvestment Act (ARRA). The technical and programmatic oversights of the AVIRIS-NG development is provided by NASA’s Earth Science Technology Office (ESTO).

Similar to its predecessor, the AVIRIS-NG is being designed to be compatible with a broad array of possible aircraft platforms, such as NASA’s ER-2 jet, the Twin Otter turboprop, and the B200 King Air.

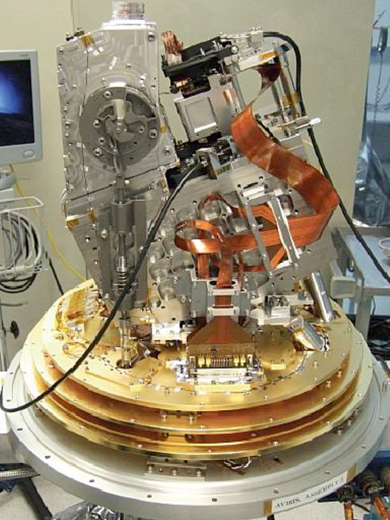

Figure 1 depicts the major components of the AVIRIS-NG flight package, include the sensor encased in a vacuum enclosure, the high precision INS/GPS, the focal plane electronics, the On-Board Calibrator (OBC) electronics source, the heaters boxes, and a vibration isolating aircraft mount.

Figure 2 shows the CAD model of the AVIRIS-NG sensor. It is approximately 33” tall by 20” in diameter. Major sensor components include the optical telescope and spectrometer benches, the detector, the source for the On Board Calibrator (OBC) and kinematic struts which suspend the assembly from the instrument backplate. The sensor is housed with a vacuum container and three thermal shields and operated at temperatures of down to -40C at the detector. Maintenance of stable temperature across the instrument is vital to minimizing thermal distortions which could affect optical alignment. Operational temperature is maintained by the operation of the two cyrocoolers. This change to active cooling from the passive cryogen approach employed by AVIRIS-NG allows operation for up to 14 days at a time with only minimal maintenance of vacuum. The key system performance characteristics of AVIRIS-NG are given in the table shown under Specifications.